EASY TO INTEGRATE AND COMBINE.

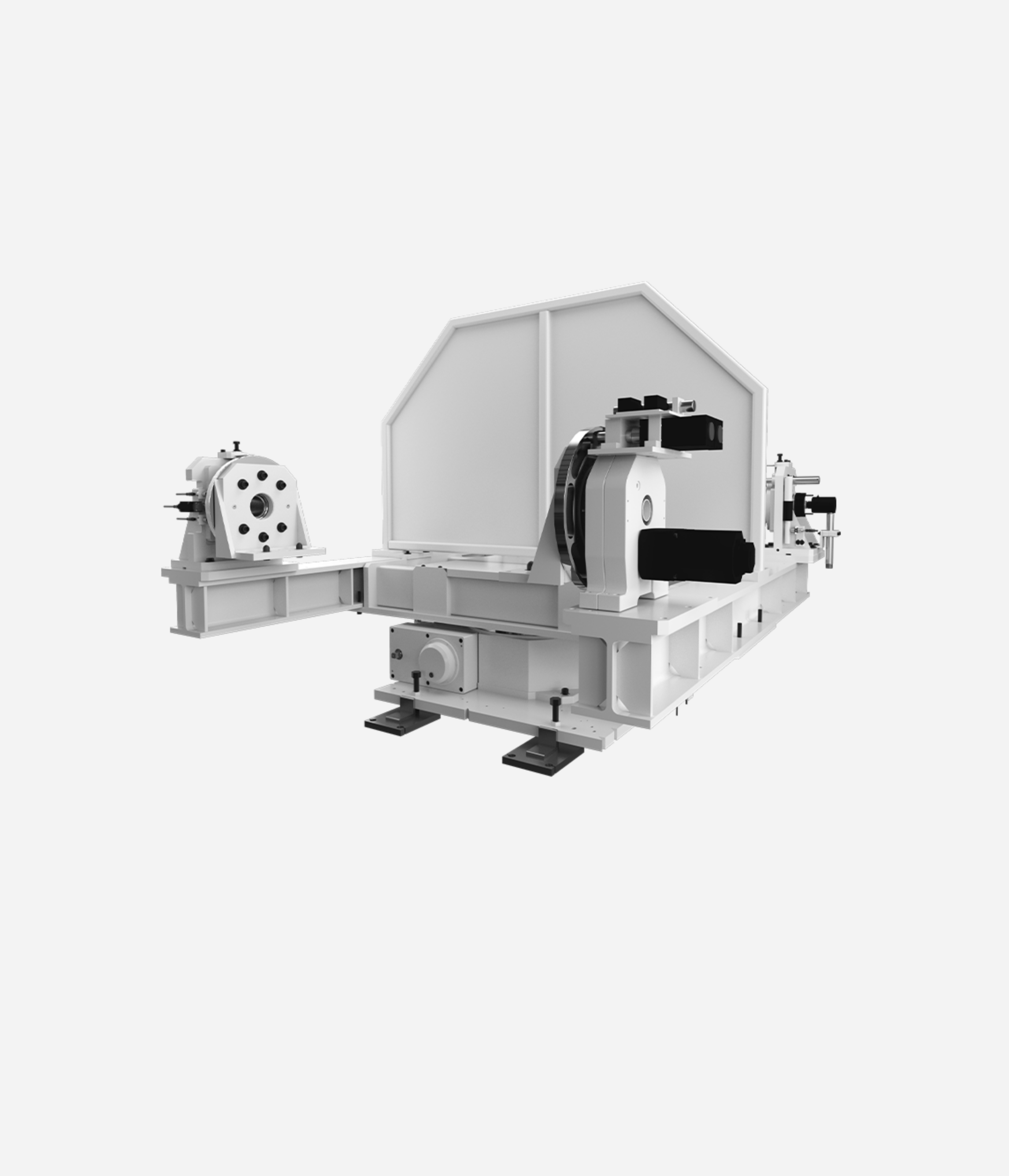

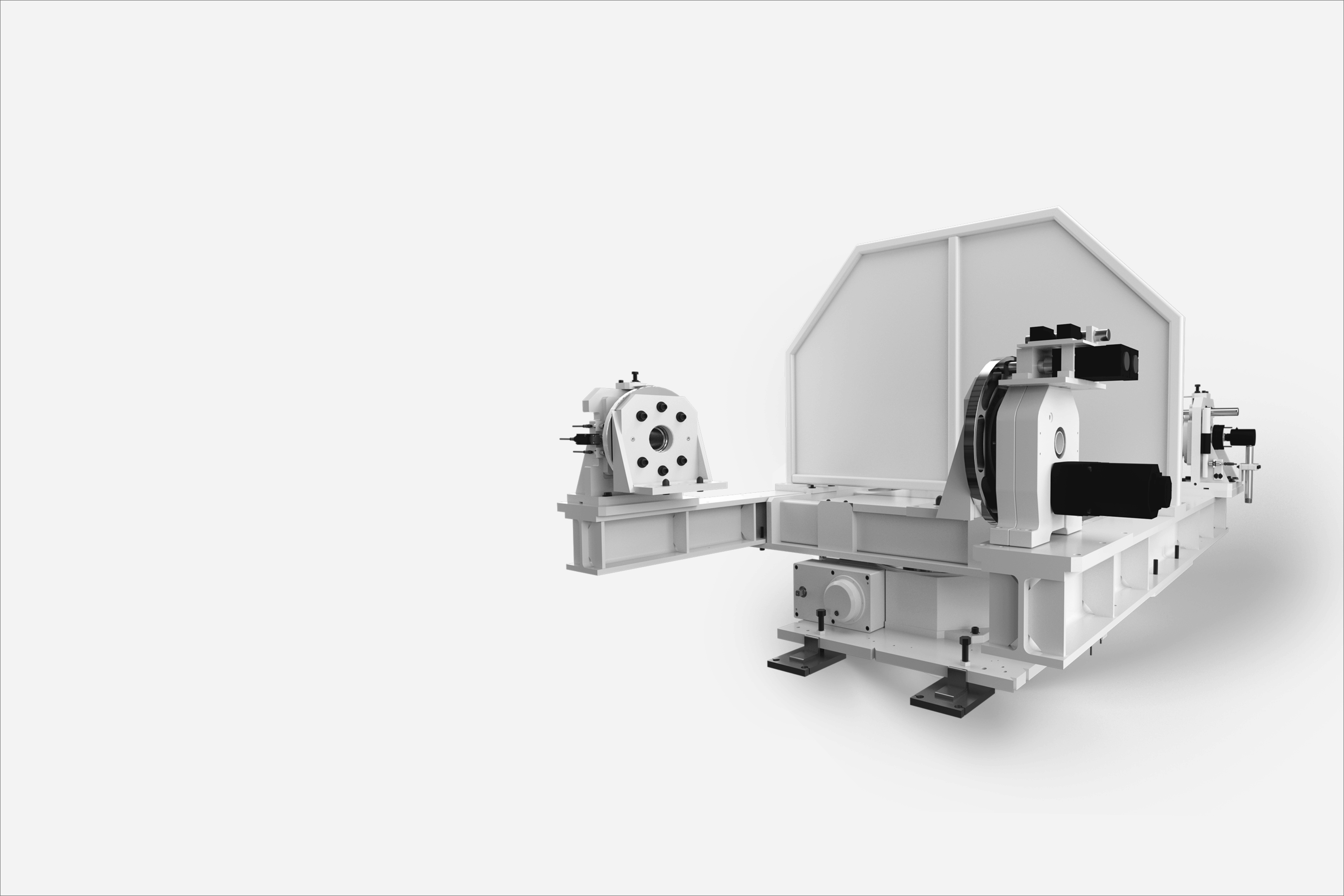

TRUNNION POSITIONER

As a complete solution consisting of multiple rotary indexing tables and a rugged frame, Trunnion Positioners augment robot applications such as welding and assembling not only in the automotive industry, but also anywhere heavy and large elements are processed.

features At a glance

- Concept

Modular - DOF

up to 3 - Integration

Platform independent

Features & Variants

TRUNNION POSITIONER

Trunnion Positioning Solutions are based on the versatile Rotary Indexing Table Portfolio from WEISS. When augmented by corresponding carrier systems, rotary feedthroughs, sensors and other application-specific adaptations, one of their benefits is that they expand the number of available axes of an industrial robot.

- Modular concept

- Standard version accuracy of up to +/-10 arcsec

- Accuracy can be adapted at any time

- Highly durable and maintenance-free

- Large center opening of up to 1216 millimeters for feed through of various media and set up of additional structures or consoles.

Have a project?

We'd love to

hear from you.

Have any questions about application areas or functions of the WEISS Trunnion Positioners? Get in touch with your technical adviser or contact us.

We look forward to your inquiry and will solve your challenge with you.